johngarnett wrote:This is where I would like clarification please.... Take full length sizer die and remove neck expanding ball on stem and replace decapping stem. Obtain a Sinclair (?) expander die and a expander mandrel for 308. Is this correct please? What are the actual parts required please? What diameter? Thank you. JohnG :cornwall:

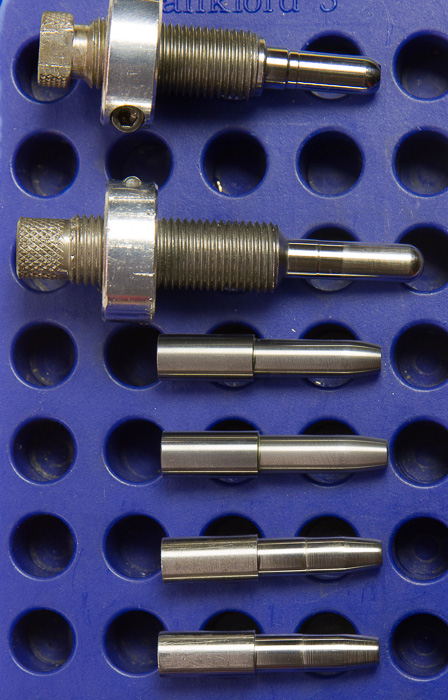

You have it exactly correct. Take one Sinclair expander die body and appropriate (interchangeable) 'E' mandrel as so:

https://www.youtube.com/watch?v=PA2U8WHHr9U

They are sold separately, so for one cartridge it is two purchases - die body + mandrel. The mandrels are interchangeable within a make of tool though, so unless you join the fifty-cal guys and need a super-size die body to accommodate big mandrels for big bad cartridges, the die body is a one-off purchase and you simply add mandrels for any different calibre cartridges swapping mandrels as needed.

Mandrels come in two sizes for each calibre - 'E' (expander) and 'T' (Turner). The E version is one thou' larger diameter than the T, the latter designed as shown in the video for the neck-turning tool. (The 'T' variant can also be used in many cases as an expander after sizing, but the resulting neck tension will be slightly heavier.)

Although designed primarily for pre-neck turning case preparation, they also work very well in most applications when used as the expander in case sizing. Others may want different amounts of neck tension on bullets, but I've had very good results with appropriate diameter Sinclair 'E' mandrels in 223 Rem, 6mmBR and SLR, too many 6.5s to mention, 7mm-08, 284, 7mm Shehane, 30BR and 308 Win BR and F-Class applications.

IIRC Stuart Anselm at Osprey Rifles makes a range of custom size mandrels for those who want more or less neck tension.

IME, you still need to lube the inside of the case-neck, especially if brass is new or is STM or otherwise cleaned to the bare metal. If you don't, stainless steel will gall on the brass and you'll soon pick up a brass film that is the devil to remove and the mandrel is usually never the same again. (Much harder / smoother 'carbide' 'E' mandrels are now becoming available, and they're widely available as an alternative to hardened steel in the 'T' role, but are much more expensive, some £40 odd last time I checked.)

In addition to Sinclair, K&M make these and I'm sure there are others around who do too. Lyman also makes a full range of mandrel expander dies sold as complete units (die body and mandrel) under the 'M die' designation.

https://www.lymanproducts.com/brands/ly ... -dies.html

Our UK distributor, Hannams Reloading stocks these.

They are particularly useful for lead-boollitt shooters (and also flat-base jacketed bullet users) as they incorporate two additional steps near the top of the mandrel and if the die / mandrel within the die body is adjusted appropriately, create a marginally larger diameter expanded section under the case-mouth then a belled mouth above that. I've used M dies satisfactorily in many cartridges over the years (but adjusted without the larger section in use for jacketed BT bullets) until the Sinclair version with its 'floating mandrel' appeared.

We used to be able to buy stuff direct from Sinclair International in the US, but after it was taken over by Brownells Inc, you have to use their efficient but very expensive UK offshoot Brownells-UK website based operation. There is of course, Mark Ellis (1967 Spud) in Norfolk and his online handloading tools and components outfit and a few other specialist retailers who do precision loading tools from Sinclair and K&M.